OE cable ladder system

The OE cable ladder system is designed to deliver high loading capacities together with significant weight reductions. OE cable ladders are designed to be safe, and give distinct HSE benefits. All parts are roll formed with return flanges and have no sharp edges. Handling, lifting and fitting operations are inherently safer, easier and quicker. All welded stainless steel products are pickled and passivated to meet the expectations of long field lifetime and integrity requirements.

-

-

Cable ladder OE125 3m

-

Cover cable ladder OE 1.5mm

-

Cable ladder OE100 3m

-

Cover cable ladder OE 2.0mm

-

Cable ladder OE150 6m

-

Cable ladder OE125 6m

-

Cable ladder OE100 6m

-

Flat elbow 90º OE150 R600

-

Cable ladder OE150 20C 6m

-

Flat elbow 90º OE125 R600

-

Cable ladder OE125 CW 3m

-

Flat elbow 90º OE100 R600

-

Cable ladder OE100 CW 3m

-

Flat elbow 90º OE150 R900

-

Flat elbow 90º OE125 R900

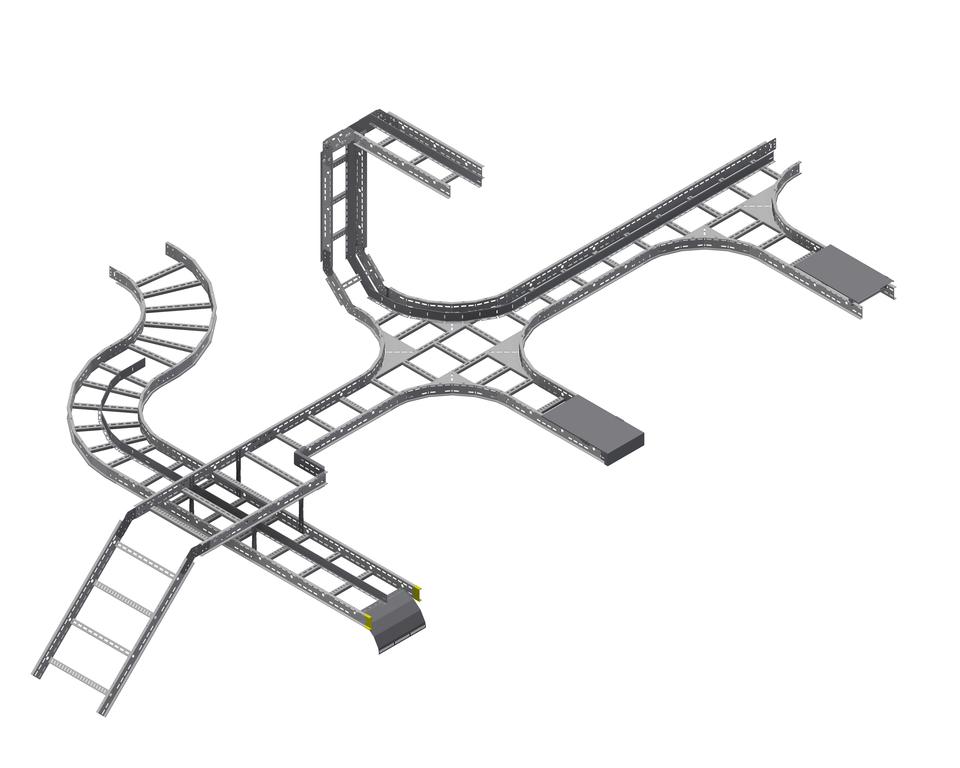

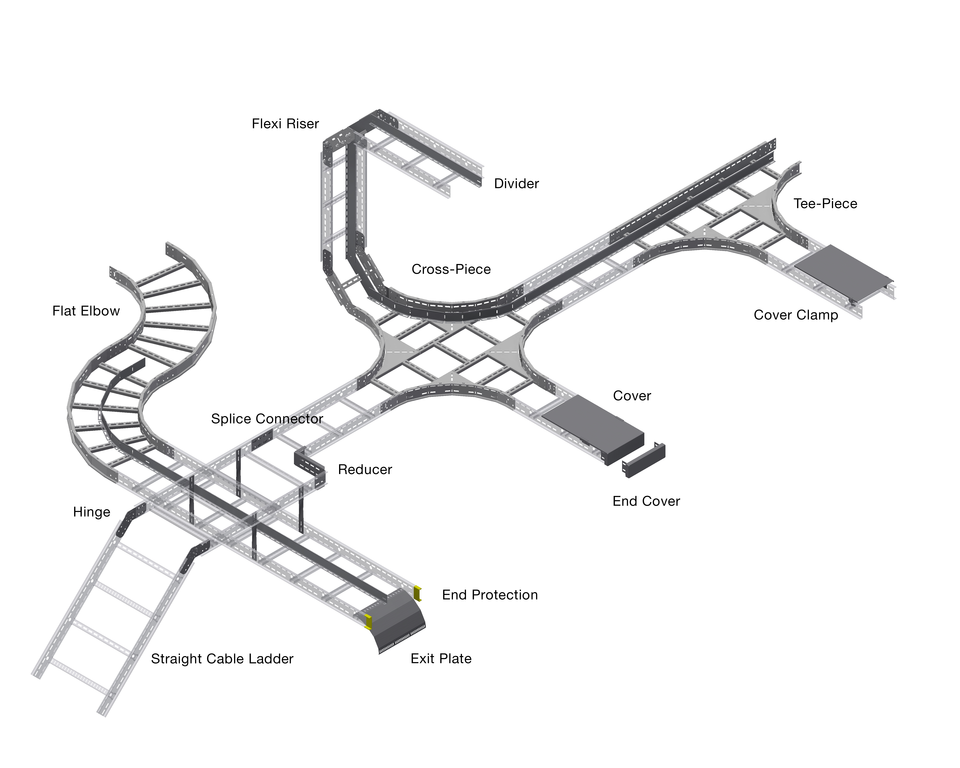

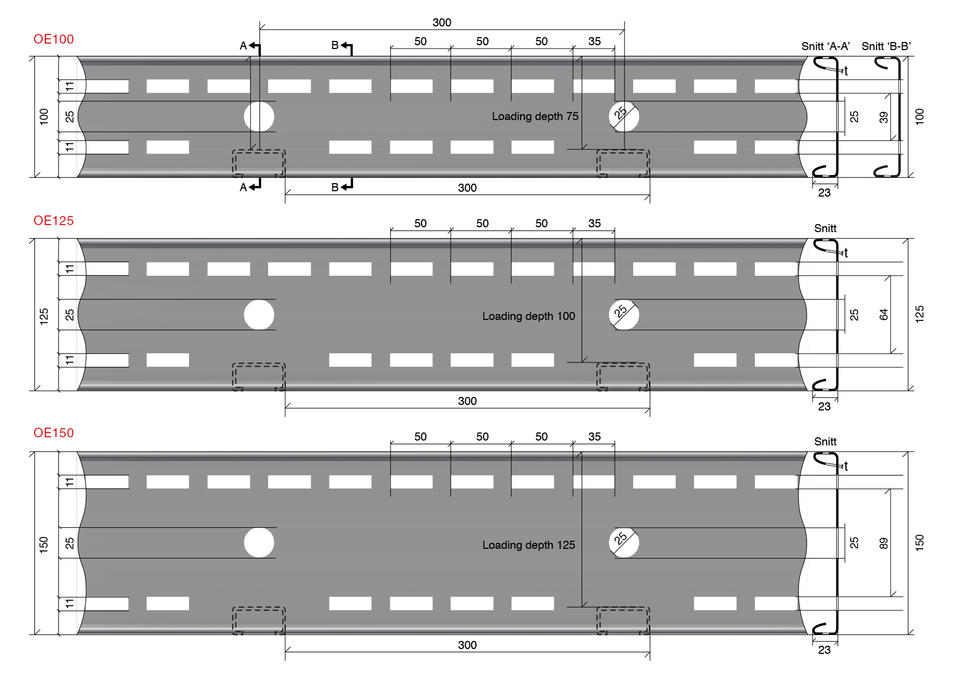

System Overview

OE cable ladder system is designed for heavy loads. Especially suited for offshore installations.

The OE cable ladder system is designed to offer high loading capacities together with significant weight reductions. OE cable ladders are designed to be safe, and give distinct HSE benefits. All parts are roll formed with return flanges and have no sharp edges. Handling, lifting and fitting operations are inherently safer, easier and quicker. All welded stainless steel products are pickled and passivated to meet the expectations of long field lifetime and integrity requirements.

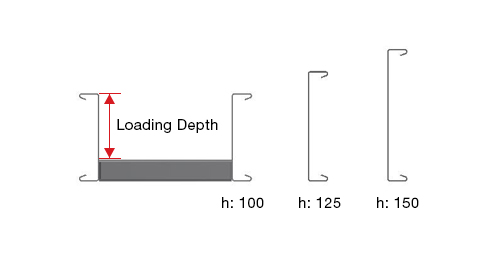

Data

|

Cable |

Rail height |

Loading depth |

SWL 3 m |

SWL 4.5 m |

SWL 6 m |

Available |

Material thickness |

|

OE100 |

100 |

75 |

283 |

164 |

92 |

3/6 |

1.5 / 1.5 |

|

OE125 |

125 |

100 |

317 |

211 |

121 |

3/6 |

1.5 / 2.0 |

|

OE150 |

150 |

125 |

417 |

221 |

122 |

3/6 |

1.5 / 2.0 |

|

OE150 20C |

150 |

125 |

- |

- |

284 |

6 |

2.5 / 2.0 |

SWL = Safe Working Load

Loading data according to IEC61537. The length of the end span must be reduced to 3/4 of the support spacing and with no splices on the end span.

Design details

Different heights (mm):

Different ladder heights offer several choices for efficient positioning of the loads and full optimisation of the area, including possibility for future expansion.

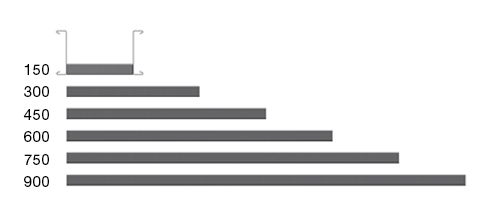

Available widths (mm):

150, 300, 450, 600, 750 & 900.

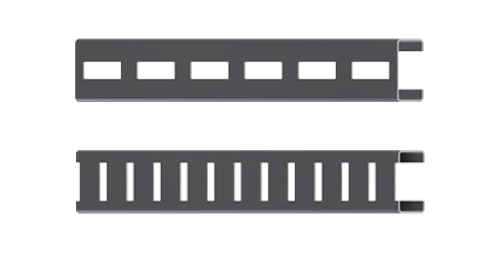

Alternating slot patterns

OE Ladders have alternating slot patterns on the rungs, allowing for optimal fitting of both cable ties, short circuit cable cleats and tubing clamps without compromise.

Drainage holes

The design reduces the possibility of any liquids to permanently gather and pool. Material choices offered have been carefully considered in order to avoid corrosion whilst maintaining cost advantages.

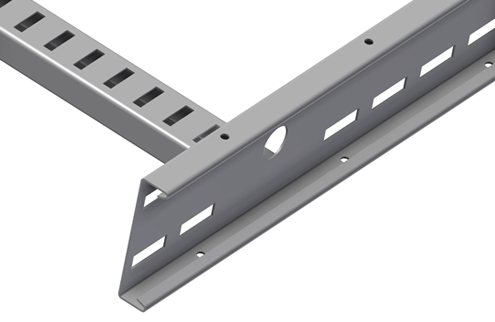

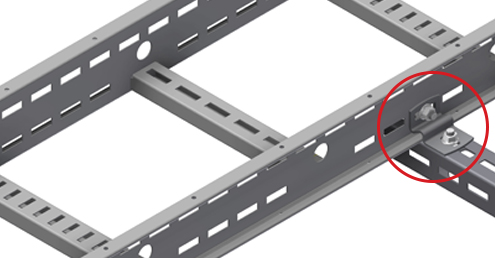

Ladder installation

Perforations throughout the length of the side rails provide simplified installation on to the support, and allow ladders to be quickly and securely connected and adjusted.

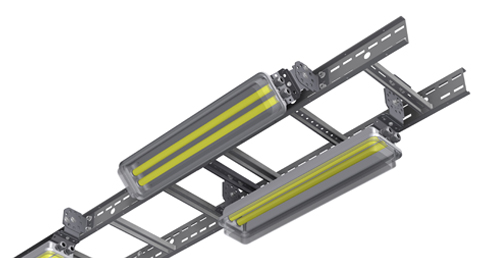

Rail & rung pattern

The rail and rung design also gives the option to connect equipment directly onto the ladder with no need for drilling or unnecessary and heavy extra bracketry.

OE Measurements

Downloads

| Name | Classification | Size |

|---|---|---|

| Catalogue / Brochure | 1318 KB | |

| Catalogue / Brochure | 1307 KB | |

| Catalogue / Brochure | 1294 KB | |

| Catalogue / Brochure | 629 KB |