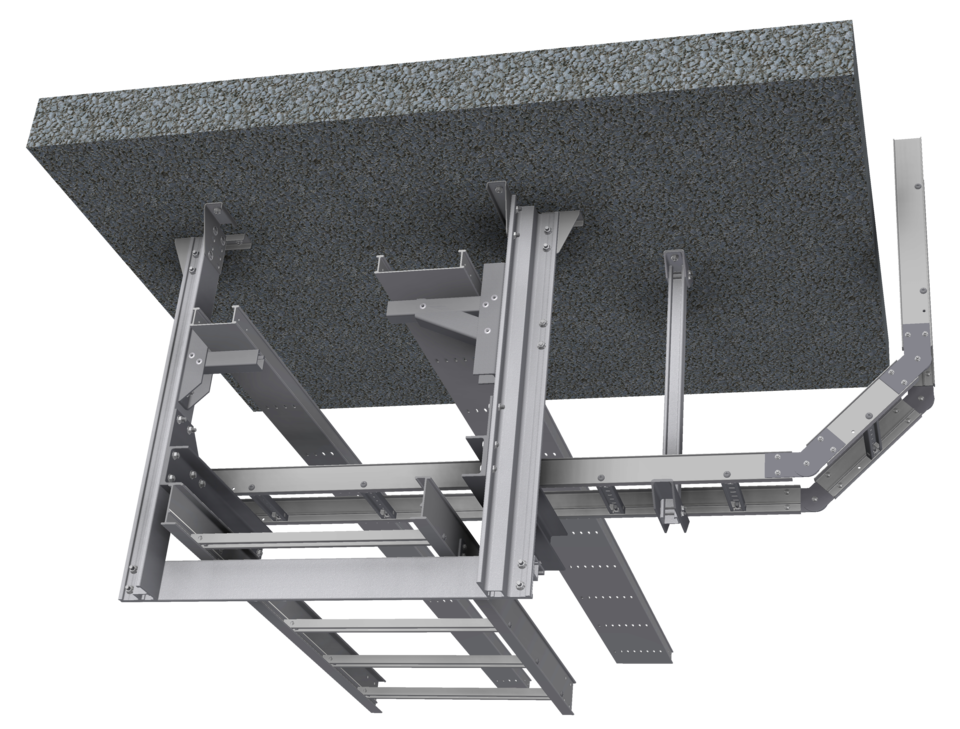

FSS support system

FSS support system in corrosion resistant fibre reinforced plastic (FRP/GRP). The support channels are designed to deliver weight reductions while maintaining strength and maximizing loading capability. The support channels are available in different resins materials, each formulated to satisfy special project requirements.

-

-

Channel FSS 100-2T (100S-1) 6m FRP

-

Channel FSS 42-1 6m FRP

-

Starter brackets FSS Z-shaped

-

Starter bolted FSS 100-1 Z-shaped FoS

-

Starter bolted FSS 100-2T C-shaped 200/300

-

Starter bolted FSS 100-2T C-shaped NP

-

Starter bolted FSS 100-2T

-

Starter welded FSS 100-2T 140/200/300

-

Starter welded FSS 100-2T C-shaped 200/300

-

Starter welded FSS 100-2T C-shaped NP

-

Tool drilling jig FSS 100

-

Tool drilling jig FSS 100-2T(100S-1)

-

Gusset plate UNO-F

-

Shim plate FSS 100-1 FRP

-

Square washer 37x50x6 M10 FRP

System Overview

FSS composite support system

Oglaend System corrosion resistant glass fibre reinforced plastic (FRP/GRP) support channels are designed to deliver weight reductions while maintaining strength and maximizing loading capability. The design delivers HSE improvements when lifting and fitting Tray and Support equipment. The support channels are available in five different resins materials, each formulated to satisfy special project requirements. To complement the support system, accessories such as gusset plates are also obtainable.

Materials

FRPCompatible systems

Design details

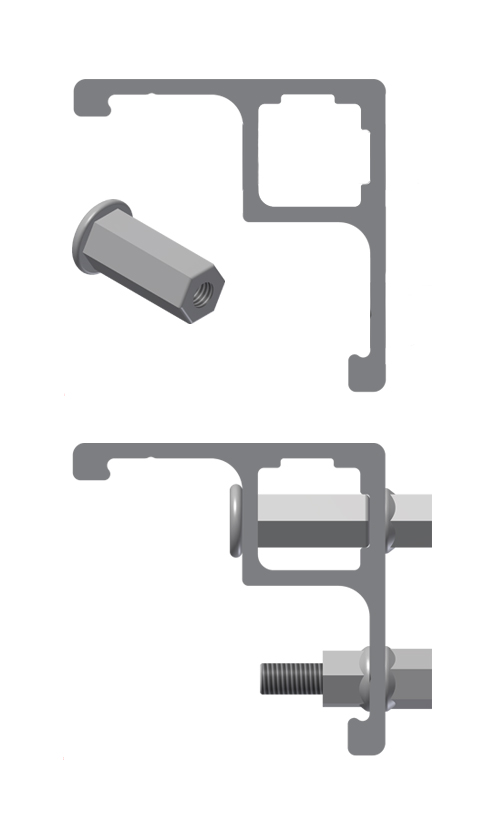

FRP Support Channel

Oglaend System are proud to present our unique, patent pending FRP support channel for heavy loads, the Triangular FRP channel. The Triangular FRP channel has been specially designed to maximise modern material and manufacturing technology for glass fibre reinforced plastics. This channel complements and develops upon our well established range of Mekano® Triangular section support profiles currently available in stainless steel and HDG materials. Reinforced woven fibre fabrics are layered in the section which provide excellent resistance to bolt shear-out and offer superior tensile strength. The closed profile box-section combined with the wide flanges provide excellent torsional resistance, and offer generous surface areas for attaching equipment quickly, easily and securely. The slots in the channels are used to positively locate our FRP Sleeve Nuts, to prevent the sleeves from turning during tightening. This allows installers to use just one hand and one tool to attach sections and equipment. This not only saves time and eases logistics, but also improves health and safety conditions. Equipment can be attached using the sleeve-nut system either through the box-section, the flanges, or a combination of them.

FRP support sections are available in a range of profiles and designs, and are available with a wide range of standard and specialised accessories in all FRP, and AISI 316L stainless steel to suit many applications.

Videos

Downloads

| Name | Classification | Size |

|---|---|---|

| Product Catalogue | 3538 KB | |

| Technical article | 1016 KB |