Our systems are carefully designed and manufactured using high tech, modern machine parks. This combination gives a product that typically has no sharp edges prior to cutting. When products are cut on-site for installation, the cut edges will in many cases be sharp, therefore precautions must be taken to avoid accidents and injuries. As common practice, we recommend using Kevlar gloves when handling and installing products in addition to eye, head and footwear protective equipment. Local and national HSE variances must also be observed.

Where products are being cut on site, we recommend using a band saw with an appropriate blade suitable for the material thickness to reduce swarf and burr. Angle grinders with fine cutting wheels can be used (1 mm). However, care should be taken to protect surrounding materials, from grinding sparks and not to overheat the materials. As best practice, any burr should be removed.

Preferred Tools/Safety

Unless appropriate safety measures are taken, cutting or grinding metal can be a hazardous activity, with a significant risk of personal injury or damage to the installation. When available, a band saw is usually the most appropriate tool for cutting thin metal products such as cable ladders and trays. Using band saws for this purpose results in minimal splatter, and its stability facilitates safe use.

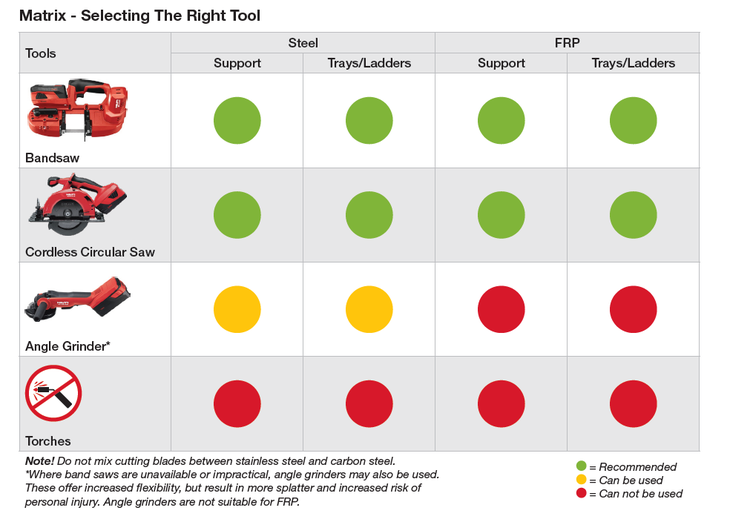

Selecting the right tool

Cordless Circular Saw

A circular saw is a good option for cutting light channels, cable trays and ladders. The Hilti SCM 22-A circular saw is precise, cordless, easy to handle and has a chip collector to reduce contamination potential. The blade of Hilti’s circular saw is guarded for the safety for the worker. It is also equipped with a blade brake that stops the blade in less than 0,5 seconds. The LED lamp in the front section of the blade guard illuminates the cutting line, making it suitable for any environment.

Bandsaw

Hilti’s cordless bandsaw is an appropriate tool for cutting low height, thin metal products such as cable ladders and trays and support channels. Accurate cutting is achieved with low noise and debris. Hilti SB 4-A22 has a cutting capacity of 63.5 mm.

Angle Grinder

Where other options are impractical, angle grinders may also be used. These offer increased flexibility, but result in more splatter and increased risk of personal injury. Thus it should be noted that safe use of angle grinders require the operator to handle it with both hands at all times. Care should be taken to protect surrounding materials from grinding sparks, and to avoid overheating the materials.

Torches

We do not recommend using torches to cut, as the surface treatment could be damaged and materials weakened.

Corrosion Risks When Cutting Steel

Due to the risk of galvanic corrosion, it is vital to avoid mixing different types of metal such as galvanized carbon steel and stainless steel. Therefore, a single cutting blade should not be used on several different materials. Nearby products of other steel types should be covered, in order to avoid particles which can contaminate the material. Damage due to mixing metals depends on the relative difference in standard electrode potential between the metals mixed. More details on the reasons for this are found on our article detailing corrosion.

When cutting stainless steel, irrespective of the cutting method, the saw blade or cutting wheel should be suitable for stainless steel. It is also important that it hasn’t been used previously on carbon steel, as the residue on the blade and wheel might cause galvanic corrosion on the stainless steel surface. This also applies to files or abrasive wheels used for deburring.

After treatment

Deburring Steel Products

After metal has been cut, all sharp edges should be deburred to avoid cutting injuries to personnel. To further reduce the risk of injuries to personnel, end caps are also available for all product ranges in high visibility thermoplastic and/or in all metal construction. As a best practice all exposed edges should be covered with end caps.

Where products have to be cut at irregular distances, we recommend having the open cut end placed inside where possible (i.e. open ends of support inside the starter bracket, open ends for ladders and trays not at the end of the cable run).

By following our guidelines and Hilti tool recommendations, it positively enhances HSE when cutting Oglaend System steel products.

Check out the complete Cutting Guideline for more extensive information.