| Material | Abbreviation | Material Quality | Surface Treatment |

|---|---|---|---|

| Stainless Steel | SS | AISI 316L (EN.14404) | Pickling and passivation (Welded products) |

| Carbon Steel | HDG, PG, PR, ZM |

Different steel qualities depending on material thickness. |

Hot Dip Zinc Galvanized (HDG), |

| Aluminium | AL | 5754 and 6060. | |

| Composite | FRP/GRP | See resin guide down below. |

Typical material certificates for given products can be supplied on request, however these requirements must be made known to us prior to ordering.

Choose the right material/coating

Oglaend System offers a range of materials/coatings to cover your needs. We recommend the following depending on your operating environment. The final decision regarding the chosen material and product is the responsibility of the user and/or specifier.

| Material | Corrosion resistance | Meets corrosion requirement class |

| Stainless steel (SS) | Very high | C4, C5-I, C5-M |

| Fibre Reinforced Polymer (FRP) | Very high | C4, C5-I, C5-M |

| Aluminium (AL) | High | C4, C5-I, C5-M |

| Zinc Aluminium Magnesium (ZM) | High | C3, C4 |

| Hot Dip Galvanized (HDG) | High | C3 |

| Pre-Galvanized (PG) | Medium | C1, C2 |

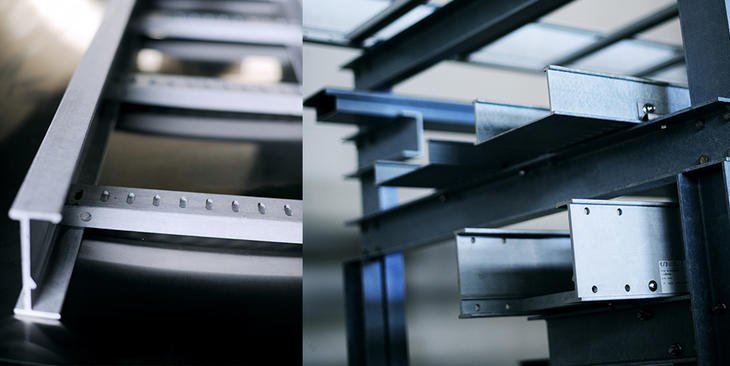

Stainless Steel

Stainless Steel (SS)

Stainless steel forms a protective chromium oxide layer when the alloy is exposed to air, hindering direct contact between the alloy and the corrosive environment. If a stainless-steel component is damaged, a new chromium oxide layer forms, effectively re-sealing the damaged area. Oglaend System's stainless steel components are usually made in AISI 316L (EN1.4404) quality.

Pickling and Passivation

Most of Oglaend System’s welded products are “pickled and passivated”. This is a process to remove the heat tint that is created during welding. The heat tint is produced by an increase in the density of chromium at the surface and a corresponding decrease in the area below. As a result, the affected region is vulnerable to corrosion and less aesthetically pleasing. Both problems are efficiently solved through the cost-efficient “pickling and passivation”, which allows a new protective chromium oxide layer to be established. Oglaend System has a long track record from the North Sea using these methods with great success.

Carbon Steel

Hot Dip Galvanized (HDG)

Hot dip galvanized steel is coated by a protective layer of zinc. The zinc layer offers solid protection against most corrosive environments. This is due to its low electrode potential, which allows it to act as a sacrificial anode. The zinc therefore corrodes slowly instead of the material it protects. Oglaend System’s HDG steel components are made in accordance with European standard EN ISO 1461. Adhering to the standard, components in material thickness from 1.5 - 3.0 mm receive a minimum 45 μm coating. EN ISO 12944-2 offers guidance that a zinc coating of 45 μm delivers corrosion protection in the order of 21-64 years in an environment with corrosion class C3. For less corrosive environments using pre-galvanized (PG) components is often a preferable alternative.

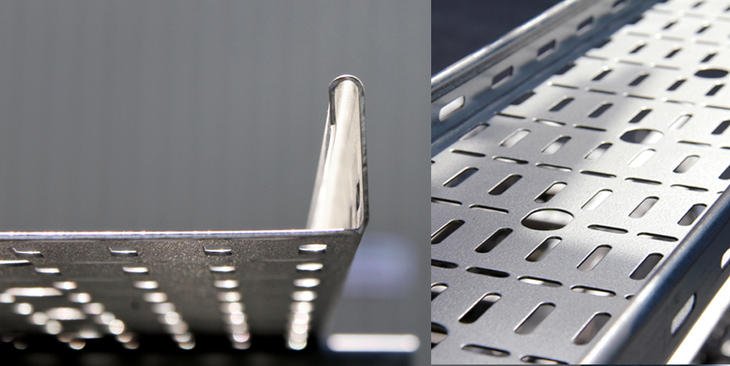

Zinc Aluminium Magnesium (ZM)

ZM is a metallic coating with excellent corrosion protection, which is suited for environments up to C4 classification. The coating consists of zinc, aluminium (3.5%) and magnesium (3%), which offers far better corrosion resistance with thinner coatings than traditional hot dipped galvanized coatings. ZM coated steel is pre-galvanized to 25 μm/ per side, which simplifies logistics and improves carbon footprint, and like HDG, it benefits from “self-healing” for cuts and holes made post coating. In addition, ZM coated products are both lighter and more cost effective than similar products in HDG finish. ZM is included in European Standard EN 10346.

Pre-Galvanized (PG)

Pre-Galvanized steel has been subjected to a process where sheet steel is coated with a thin layer of zinc, which gives it a bright appearance. This zinc layer of 20 μm thickness in accordance with EN 10346, offers protection due to its low electrode potential and slow corrosion rate. As the process is carried out on raw materials prior to cutting and bending. Products in PG are suited for installation in environments with a low corrosion rate.

Painted/primed products (PR)

Certain products are delivered factory primed, which acts as a protective coating during transport and storage, thus preventing corrosion. When the products are exposed to corrosive environments, a secondary coating must be applied to ensure optimal life expectancy. The primer has good adhesion and gives the topcoat maximum coverage.

Coated products (WE)

Where aesthetics or additional surface protection is relevant, some products can be supplied with surface coatings such as epoxy powder coating. These coatings are available in a wide range of colours on request. Coated products require local site removal of coating to provide bonding connection points and additional earthing jumpers.

Aluminium (AL)

Aluminium is typically used in applications where minimal weight is key. When exposed to water it forms a coherent surface oxide preventing the aluminium to corrode. Oglaend System’s aluminium components are made in 5754 and 6060 quality.

Composite Materials (FRP)

Resin Choice

Oglaend System offers a range of resins to match the needs of our customers. From our standard polyester resin to our high performance options, we can meet your chemical, fire, smoke and toxicity requirements. Please contact our technical team with your individual project requirements for tailor made solutions.

GRP/FRP: Note, the pultruded process of manufacturing means there is no difference in GRP/FRP material types.

Polyester (FRP)

Resin Code: standard article number

Polyester is the most widely used resin system. It offers good weathering properties with resistance to ultraviolet light and has good corrosion resistance. The resin can also be formulated to meet specific fire and smoke standards and can be supplied with conductive properties. Our standard polyester resin product range is UL approved.

Polyester with anti-static properties

Resin Code: ’C1A’

Polyester resin can be given anti-static properties to meet project requirements. Anti-static resins contain carbon powder, which increases the conductivity of the material and as a result this material requires grounding.