Oglaend System usually gets involved with engineering support in the early stages of a project. That way we can help customers maintain control of project expenses and provide solutions that reduce the levelized cost of energy (LCOE).

Detailed design

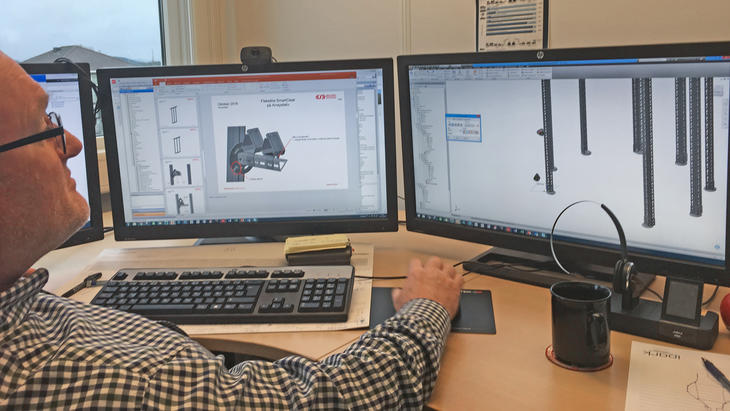

We have core expertise in providing detailed design solutions for TPs, jackets and substations. Close dialogue and cooperation with the client is a major part of our design process. The result is often reached by exchanging STEP-files with the customer’s engineering department.

Our technical designers can be stationed at your engineering-house or yard to do detailed design. Together with the customer we will define the design and come up with the most suitable solutions. By doing so, our designer will be able to extract complete BOM-lists directly from the 3D-model. The list contains all the necessary parts and complete pricing for the project – even nuts and bolts are included in the list. The total project costs are therefore easier to estimate.

Design of TPs, jackets and substations

There are some special considerations that must be made when designing jackets, transition pieces and substations. It is important that applications such as: ICCP, sonar equipment, light fixtures, crane panels, socket plates, structural welds, hang-offs, switchgears and array cables are coordinated together with both the electrical and structural engineering departments. This coordination is key to achieve a successful project.

Structural analysis tool

Our newly developed structural analysis tool, Precision for Decision (P4D), can produce detailed reports of our systems' capabilities. It is especially useful when it comes to calculating loading capacities of heavy-duty supports for array cables.

We also use P4D to verify tolerances of our supports when it comes to seismic movement, such as earthquakes.

Workshops and training prior to installation

We often have workshops with the customers and installers before the installation of cable support systems is due. This type of training helps ensure that the installation is efficient.

A Project Manager appointed by Oglaend System will supervise the first batch of materials on-site. We want to ensure that materials are supplied according to the agreement and that there are no damages. The Project Manager can also provide training for staff to make sure products are assembled correctly. Assemblies that can be pre-assembled before final installation will also be controlled during the support session.

Please contact our coordinator for wind projects to get more information about how we can support your project.