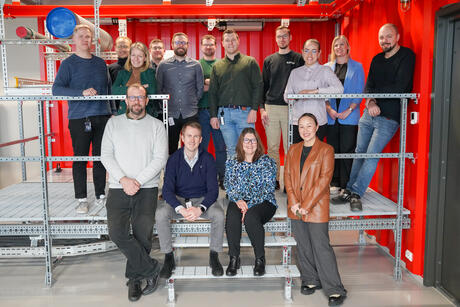

NCC is the contractor for this project called R300 and chose to use Oglaend System’s support solutions in the entry tunnel and in other tunnels to support all disciplines.

The Käppala wastewater treatment plant outside of Stockholm is in the process of constructing a new sludge-digestion compartment to deal with increasing amounts of wastewater. At the same time, a new facility for high-flow wastewater is constructed to keep up with future treatment requirements. The plant already receives wastewater from eleven municipalities in Storstockholm, which equates to about half a million people.

At the start of the project, a welded solution had been specified for all the support systems. However, after Ögländ System AB showed how our products were more cost effective, quicker and easier to install, they decided to use Oglaend System’s products in the tunnels where a welded solution had not already been ordered.

In an earlier project, we used Ögländ System AB’s solutions, and when I came to this project there was another solution that had been specified, but it was difficult to install. There are many requirements to consider with water treatment plants, which is why we chose Oglaend System's bolted solution over a welded solution. We will finish installing the support systems this week and are very pleased with them.

- Christian Jonsson, Project Manager NCC

After construction is completed, the new sludge digestion compartment will work to relieve the two existing compartments. Here climate friendly biogas that can supply 100 gas fuelled busses is extracted. While the high-flow facility will handle situations when amounts of wastewater breaches the Käppala plant’s capacity. Considering the climate changes, this is an important environmental measure that enables faster and more thorough treatment of the water that is discharged.