-

Gearing up for demo bus tour of Denmark

Oglaend System’s modular support systems are now on wheels and ready to roll to your workplace. Our upgraded demo bus is filled with cost efficient support solutions for EI&T, piping, maintenance & modifications, and firestop cable transit system.

-

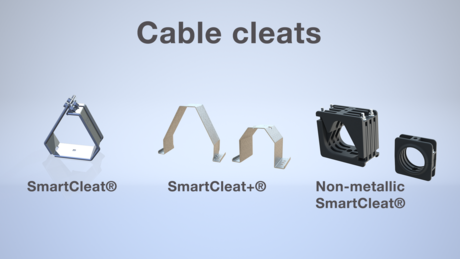

Which cable cleat should you choose?

To use cable cleats is an important safety precaution in case of a short circuit event where substantial damages to cables and surrounding installations could occur, and more importantly, to safeguard personnel against potential injuries. A cleat will keep cables tightly secured during operation and in case of short circuit events.

-

APQP4Wind training to meet requirements of wind industry

As a supplier to the increasingly competitive wind industry, it is important to examine how we can improve our quality assurance processes.

-

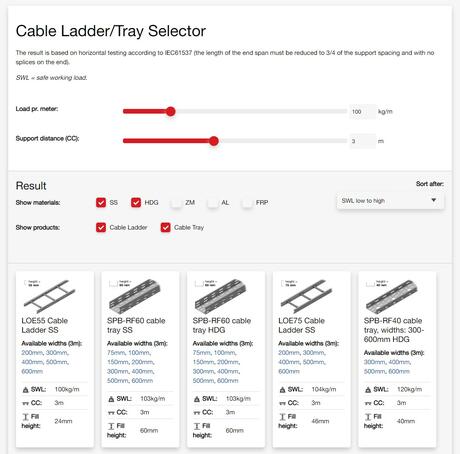

Making selection of cable ladders and cable trays easier with new selector tool

With a range of cable ladder and cable tray solutions available it can be challenging and time-consuming to find the best fit for your project specifications.

-

Will we see you at the Offshore Northern Seas (ONS) exhibition in Stavanger?

We’re thrilled to be back at the ONS exhibition again! These past years we have been working on a range of new products & solutions that we will showcase in hall 7 stand number 7270.

-

Fibreglass system at fish hatchery in Norway

«Lerøy Midt» are looking to increase their production at the fish hatchery in Belsvik in Trøndelag and to do so it was necessary to expand the existing facility. Our sales engineer, Nora Fotland, visited the facility to see the final result and get feedback from West Elektro on how they found our support system in FRP (fibre-reinforced plastic).

-

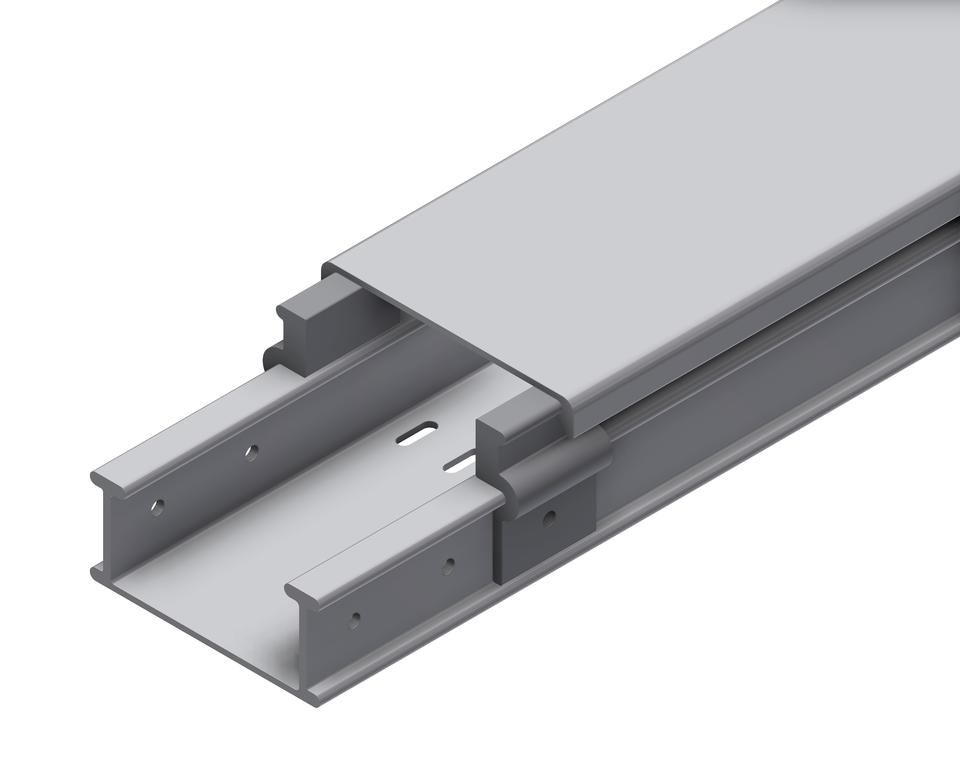

NEW High Corrosion resistant LOE Cable Ladder

The economical and low weight cable ladder, LOE75, is now available in the corrosion resistant material ZM (Zinc-aluminium-magnesium) from our factory in Norway. ZM coated material has superior corrosion resistance compared to traditional hot dipped galvanization (HDG) and is more cost effective. It even has a self-healing effect, which provides protection to cut edges and perforations. One of many reasons why we recommend ZM material for environments up to C4 classification.

-

The Product Catalogue 2021 is ready!

A new and more comprehensive version of the Product Catalogue is now available for download. We invite you to have a look through our product news for offshore application.

-

FRP Clamp to elevate cover and improve ventilation

By utilizing our raised cover clamp solutions together with our cable trays with covers you are rewarded with more available space inside the tray and significantly improve ventilation to keep cabling cool.

-

Smart solutions for Shipbuilding

Our goal as a partner is to improve our system solutions to make our customers more competitive.