Eliminating maintenance related costs

In the wind energy industry there has been major challenges with corrosion, especially on substations. Entire platforms could be completely red with corrosion before even leaving the yard.

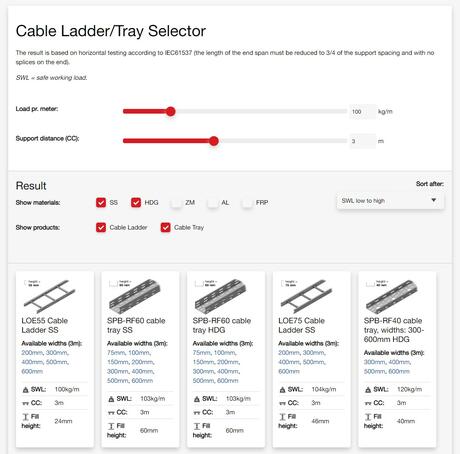

Oglaend System can offer a complete support system in FRP-material, which eliminates any corrosion related maintenance of cable support systems and earthing connections. The FRP system is especially well-suited for substations, where expensive maintenance is not desired.

Less retrofitting with kits & cuts

Our companies in Denmark and Netherlands offer kitting and cutting of products for transition pieces (TPs). Our deliveries can be installed straight out of the box, which reduces costly and time-consuming work on-site; as well as preventing retrofitting work.

We have local production for cutting materials to the required lengths, which means that the customers will not have any excess material or material waste to take care of. Minimal cutting and grinding is required on-site, which reduces the risk of harm for the customer.

We also offer “just in time” delivery, which means that our systems and products will be delivered just before the cable support systems are scheduled for installation. That way our products will not be taking up warehouse space over a long period.

All deliveries are packed and labelled with a customer specific article number, which includes all accessories such as bolts and nuts. Picking and packing products is done beforehand, so it is not necessary to organise the parts on-site, instead the products can be installed straight out of the box.

We have already delivered TP kits to several projects such as: Galloper, Beatrice, Rentel, Abeerdeen Bay, Hohe See, Horns Rev 03, Horn Sea 01 and Deutsche Bucht.